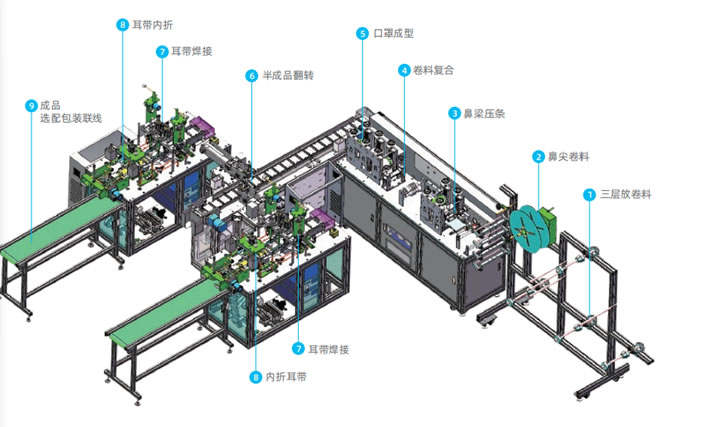

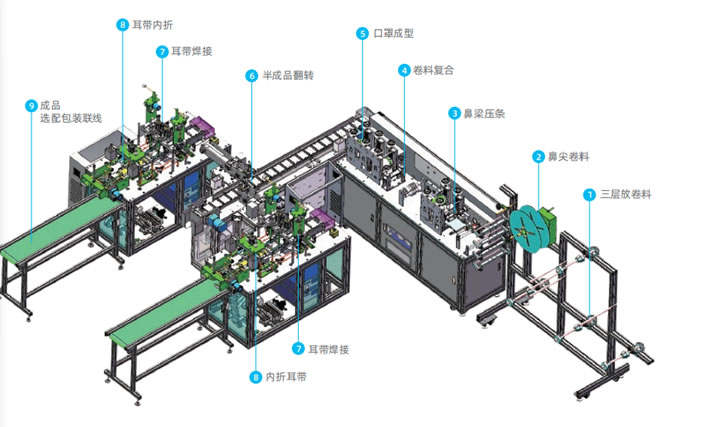

Machine Description:

One unwinding double full automatic mask production line adopts advanced design,only need put the raw material on the feeding rack.After the completion of the modulation.the machine can up to automatic working. It need 1 worker and do the automatic producing.The equipment adopts ultrasonic welding,which is beautiful,sanitary,environmental friendly.

The output is 100-120pcs/min,The length of nose bridge bar can be adjusted.The product size error is +1mm, According to the needs,replacing parts of the molds can achieve a variety of specifications of mask pieces.This machine can produce all kinds of non woven masks,smooth cloth masks,gauze masks,activated carbon masks,double-nasal line masks.Support 1-5 layer of non woven mask sheet production.

Machine parameters:

Machine Model: CCE-1950-2

Capacity:100-120pcs/min

Voltage: 220v 60Hz

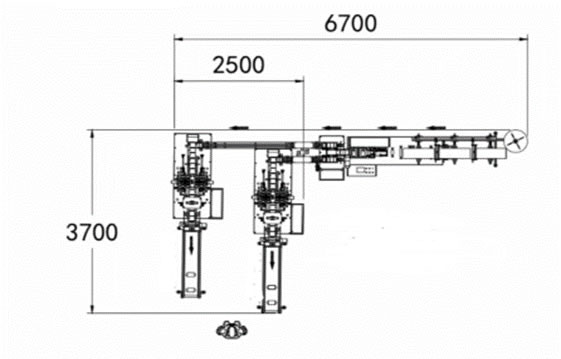

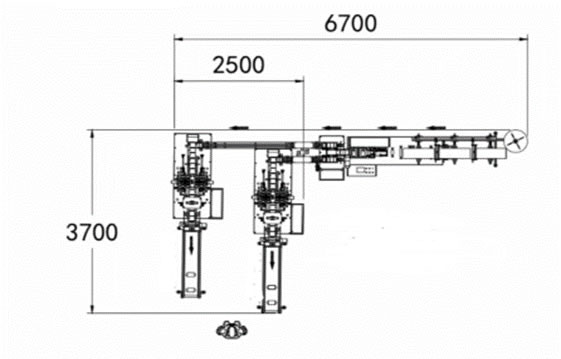

Machine Overall size:6400*3200*1680mm

Mask size:17.5*9.5cm

Weight:1700kgs

Mask material feature:

Melt-blown fabric:width 71.5cm, weight :20g

Non woven fabric:1.width 17.5cm,weight :20g;2.Width 19.5cm,weight :25g

Nose bridge bar:width :3mm ,thickness:1mm, length:95mm

Ear belt:width:2.5mm,length:200mm

Mask making machine technical parameter:

Overall dimension: 3345*630*1830mm

Voltage: AC 220V,50/60Hz

Speed:100-120pcs/min

Power:2.7kw

External ear-loop machine technical parameter:

Overall dimension:1915*855*1780mm

Voltage: AC 220V,50/60Hz

Speed:150-60pcs/min

Power:2.7kw

Sample: